Technology

Home / Technology / Chain Link Fence & Anchor Bolt Support Technology of Rock RoadwaySolve Roadway Support Problem of Soft Broken Surrounding Rock

CLFSR-01: Numerical simulation and experience help the construction of chain link fence rock bolting.

CLFSR-02: The surface displacement curve of soft rock roadway.

- The test of mine geological and production conditions

A working surface of the 5–2S coal mine area is mining 5–2# coal and the 5–1# coal seam covered on that coal seam has been mined. The distance between these two coal mines is small. Within the working surface, the minimum distance from the roof of 5–2# coal seam to the baseboard of 5–1# coal seam is 6 meters, and the maximum is only about 9 meters. The average thickness of 5–2# coal seam is 5.99 m, containing several layers of gangue. The dip angle of coal seam is 15°–16°. The uniaxial compressive strength of coal seam is only 4.8 MPa, with bedding and joint development. The strength of sandy mudstone on the roof is 15–25 MPa and the bottom is the same material. Its uniaxial compressive strength is about 23.5 MPa, with expansibility. The method of hydraulic fracturing is used to measure in-situ stress. The maximum horizontal principal stress is 14.62 MPa and the direction is N72° E. At the same time, the minimum horizontal principal stress is about 7.35 MPa and the vertical principal stress is 9.68 MPa. The experiment was carried out on the working face of 5–2S coal mines' traffic lane and return air lane. The following is taken it as an example. The heading section of the air return tunnel is a straight wall semicircle arch whose width is 3.8 meters and height is 1.2 meters. Its excavation area is 10.2 m2 and the depth of the tunnel is 350–400 m. - The design of roadway support

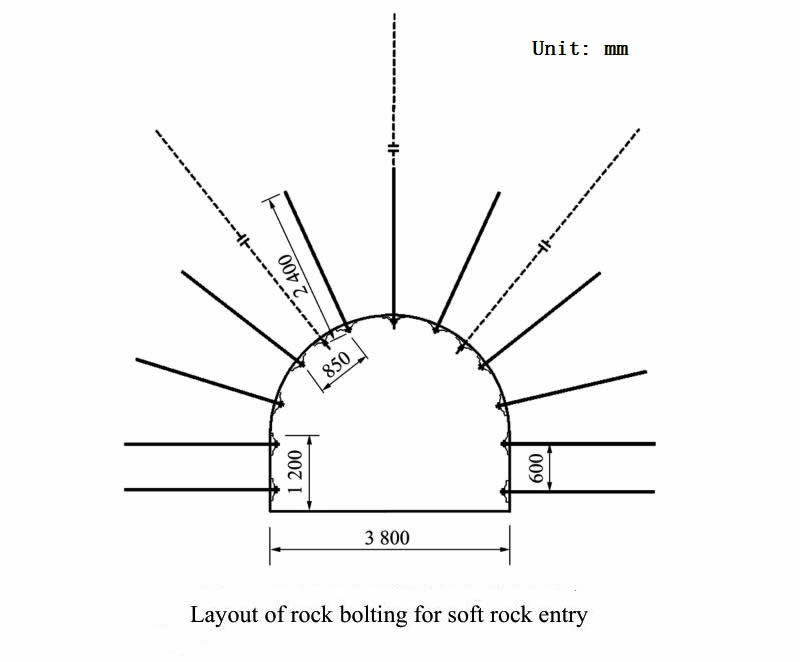

The numerical simulation is used to compare the different schemes, and the existing experience is used to determine the full length prestressed anchor combined support in the roadway. The body of anchor rod adopts 22-millimeter-diameter vertical reinforced concrete anchor rod, whose length is 2.4 m. The whole length of the resin is anchored, the end of which is made of fast curing anchoring agent, and the slow curing anchorage is used at the back. Its roof adopts W type steel guard plate, welded steel bar for roof plate and 4 mm galvanized steel wire chain link mesh with 50 mm mesh opening for surface protecting component. The anchor bolts are perpendicular to the roadway surface. Each row has 7 floor bolts with spacing of 850 mm and row spacing of 900 mm. The distance between the top plate and the two anchor bolts is 600 mm with each row of 2 anchor bolts. It pre tightening force is 400 N·m. The cable body is 22-millimeter-diameter steel strand of 1 × 19 and its length is 4.3 m. After anchoring, the end of the resin is prestressed. There are 3 anchor cables every 1.8 m with spacing of 1.28 m. In addition, the pre tightening force of cable is 200–250 kN. The arrangement of bolt support in soft rock roadway is as shown in the following figure: - The analysis of downhole monitoring data

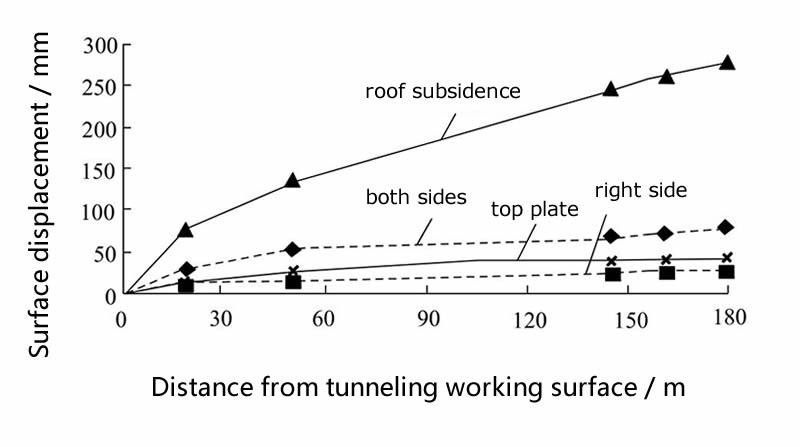

During tunneling, the surface displacement curve of soft rock roadway is as shown in the following figure:

The surface displacement tends to be stable after 53 meters from the tunneling working face. The displacement of both sides is 79 mm, the upward displacement is 46 mm, and the downward displacement is 33 mm. The top and bottom displacement is 281 mm. The roof subsidence is 43 mm and the amount of floor heave, which accounts for 84.7% of the top and bottom displacement of the roadway, is 238 mm. The large amount of floor heave is caused by no supporting on the floor. The shallow bed separation of roof is 14 mm, the deep one is 23 mm and the total separation is 37 mm. For a period of time after being installed and prestressed, the force of anchor bolt becomes smaller. With the advancing of tunneling working face, 19 meters above the working surface, the force of the bolt increases gradually. The force is gradually stabilized after 119 m from the working face. In the process of installation and force stability, the force change of full-length anchoring bolt is small. Some anchor bolts' magnitude of the force change is in the range of 8–9 kN and most of anchor bolts is within 5 kN. After being installed and tensed, the force change of anchor cable is not large. When the working face is 21 m from the tunneling face, the force of anchor bolt is kept stable. The roadway deformation is small and the surrounding rock is kept intact during the whole excavation. Underground support in soft rock mining roadway is as shown in the following figure:

CLFSR-03: Chain link fence and anchor bolt support makes the surrounding rock of roadway complete and stable.

During the extraction of coal face, workers reset the displacement measuring station on the surface of roadway and observe the force of anchor cable in detailed. Roadway in mining face from 40–50 m is significantly affected by mining and the displacement also increases visibly, especially after 30 meters. At the position of 3 m from the coal mining face, the displacement of both sides reaches to 256 mm and the roof subsidence is 110 mm. The anchor cable grows slowly at the position of 100 m from the coal mining face. Its growth rate increases significantly at the position of 56 meters from the working surface and reaches the maximum gradually. When reach the parallel position of the working surface of coal mine, the force of the anchor cable is more than 200 kN.

All in all, the surrounding rock of roadway is complete and stable. Its total deformation is small enough to meet the needs of safe production.

Recommended specifications of suitable chain link mesh for coal mine supporting:

- Material: low carbon steel or galvanized steel wire.

- Wire diameter: 2.0–4.0 mm.

- Mesh size: 5 cm × 5 cm, 6 cm × 6 cm, 8 cm × 8 cm.

- Roll size: 1 m × 10 m, 1.2 m × 10 m. Special sizes can be customized.

- Edge type: knuckled edge.